NETZSCH

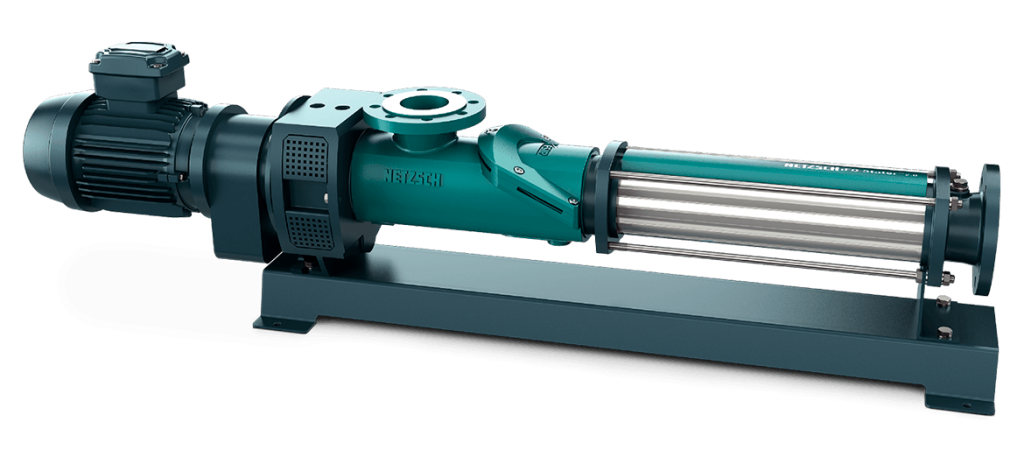

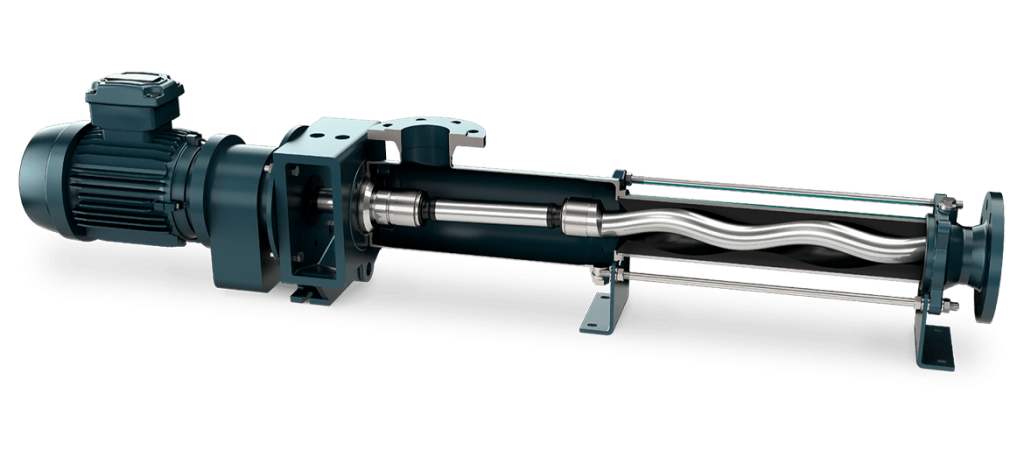

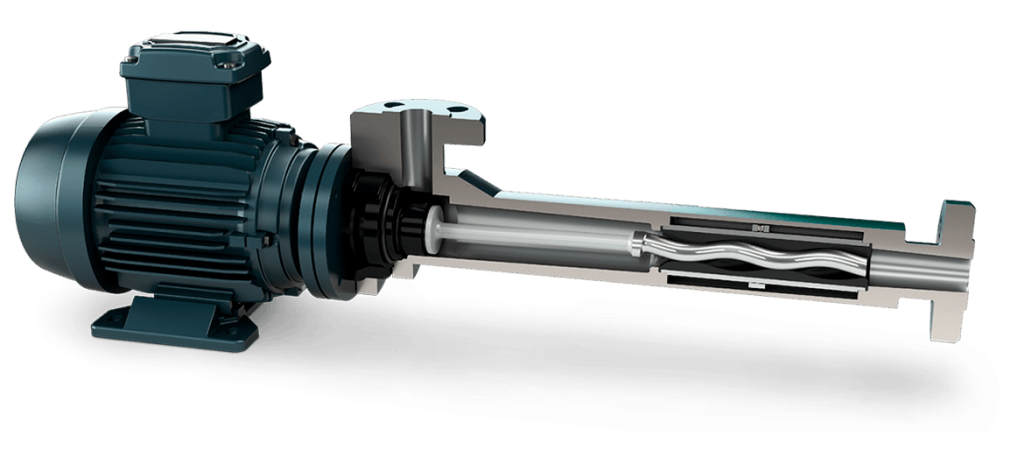

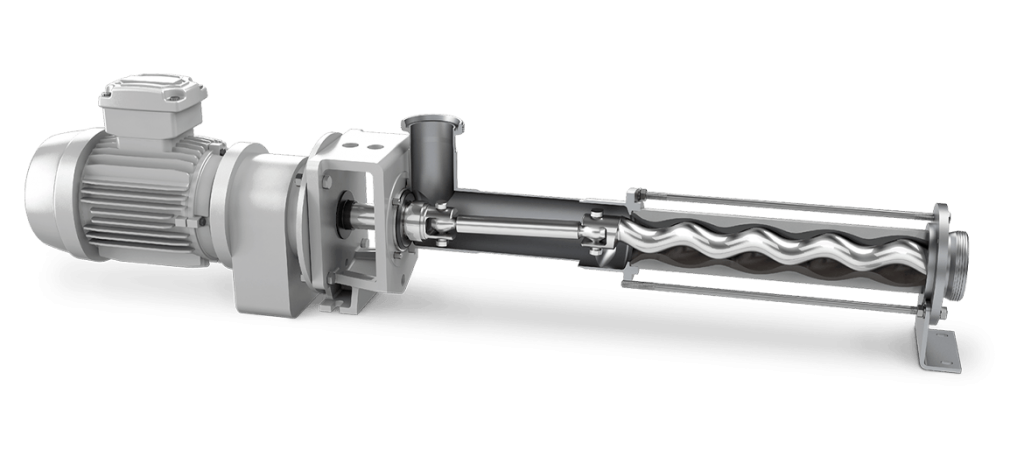

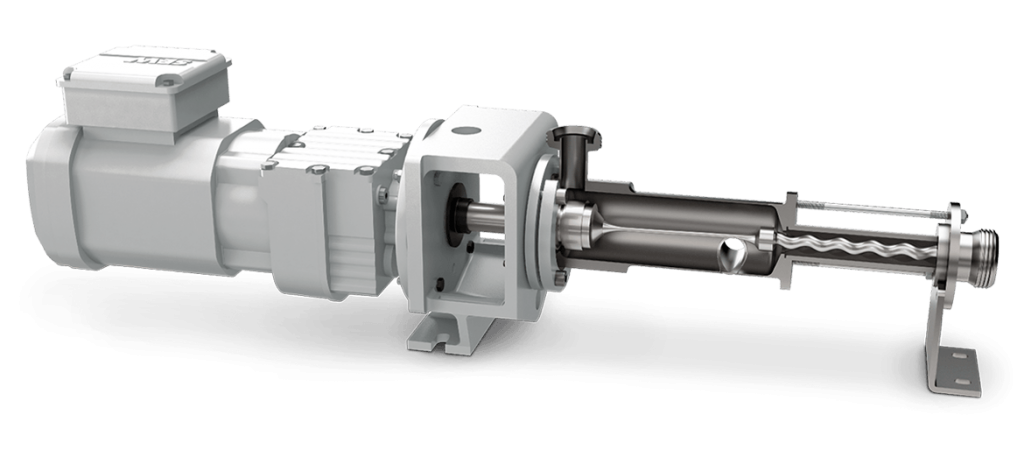

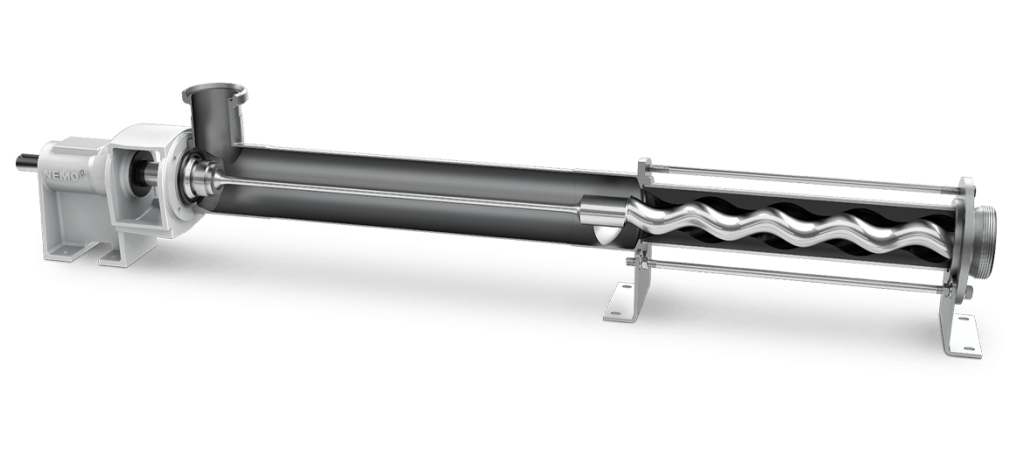

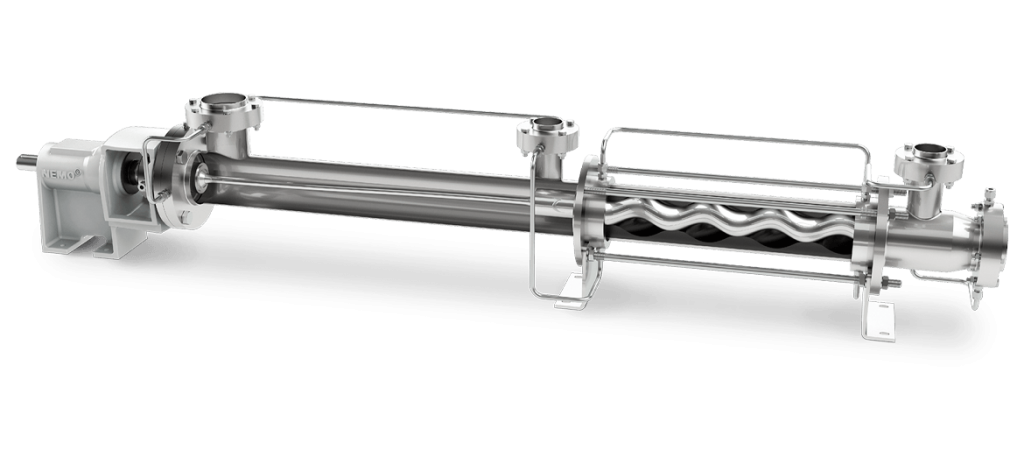

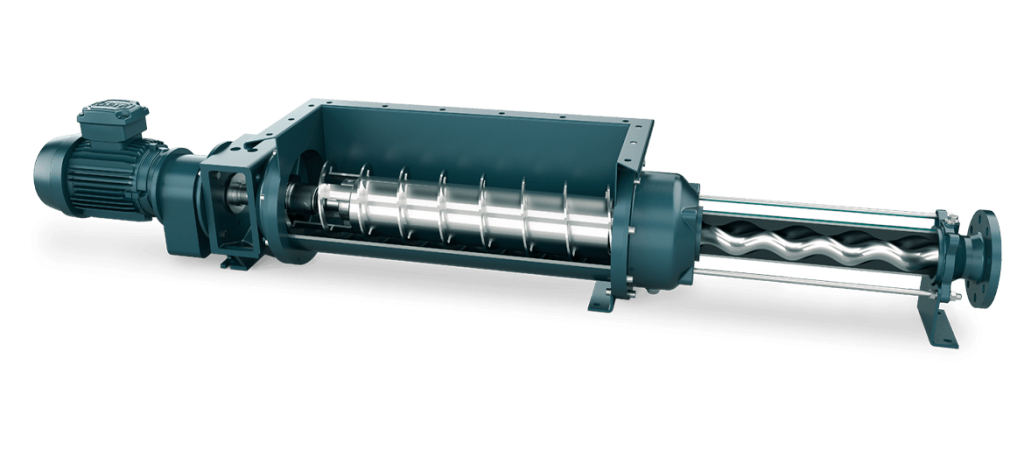

NEMO® progressing cavity pumps have a very broad application range and are used in all branches of industry for the continuous, pressure-stable, gentle and low-pulsation conveyance of almost any substance.

One advantage for the operator is that such valveless positive-displacement pumps are also capable of transporting stringy material safely. Whether for sludge, chemical substances, adhesives, petroleum or yogurt, one of the eleven pump types by NETZSCH in four rotor/stator geometries selection of engineered joints make sure to suit your application.

To further increase the service life of NEMO® progressing cavity pumps in wear-intensive applications, NETZSCH Pumps & Systems has developed a special stator adjustment unit, called xLC® unit, which is based on the easy-to-replace and easy-to-maintain iFD® stator 2.0.

If the sealing line between the conveying elements rotor and stator fails due to wear, compressing the elastomer can easily and quickly restore the pre-tensioning, and with it the pump performance. Moreover, an integrated display provides information about the readjustment status of the stator and when a stator change is impend at all times. Thus the tool ensures more operational and planning safety. To minimize the wear, the xLC® system canbe combined, for example, with joints and seals as well as special wear coatings for rotors.

Product Range of the NEMO® Progressing Cavity Pump

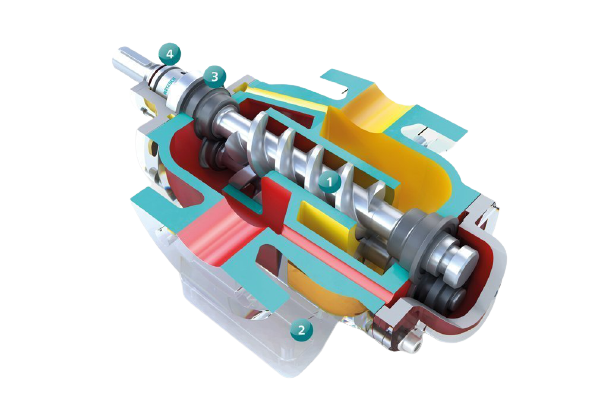

NOTOS Multi Screw Pumps

Since 1979 NETZSCH has been manufacturing multi screw pumps to serve a wide range of industries and applications.

The most advanced technology is utilized to produce these pumps.

Operational reliability, durability and years of experience in the pump sector are some of the reasons why you should choose NOTOS® screw pumps from NETZSCH. NOTOS® pumps are designed to convey low to well lubricating fluids, low to high viscosity, shear sensitive or chemically aggressive media.

Our range of metallic materials extends from grey cast iron and chrome-nickel steel to duplex, super duplex or hastelloy steel. Further metal material options on request.

- No dynamically loaded rubber parts

- Static seals from NBR to FFKM

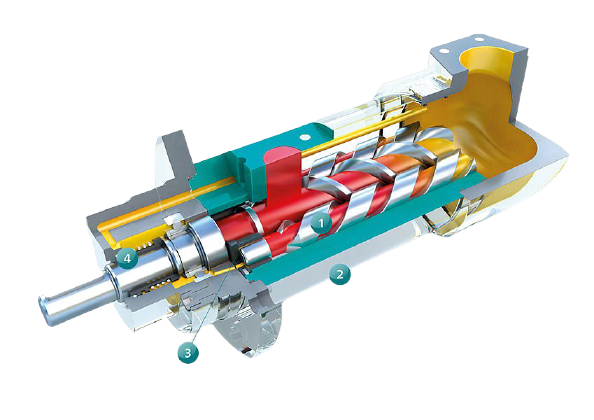

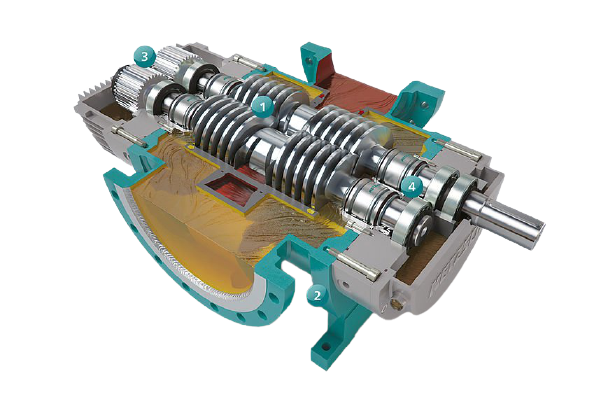

NOTOS® Multi Screw Pumps are known as pumps for low to high flows and low to high pressures.

- Flow rate up to 1500 m³/h

- Pressure rate up to 80 bar

- Viscosities up to 50.000 cSt

- Temperature up to 300 ºC

- Self-priming

- Good suction capability

- Continuous flow with low pulsation

- Flow with minimal turbulences

- Gentle product handling

- Low maintenance

- Low lifecycle cost

- Long service life

- Quiet operation

- Several mechanical seal options

- Magnetic drive optional

- Extremely low noise and vibrations

The NOTOS® multi screw pump family comprises three series in multiple arrangements which serve a wide range of industries and applications. The superior quality standard meets the highest level of requirements from our customers. Three different pump series to meet your individual demands:

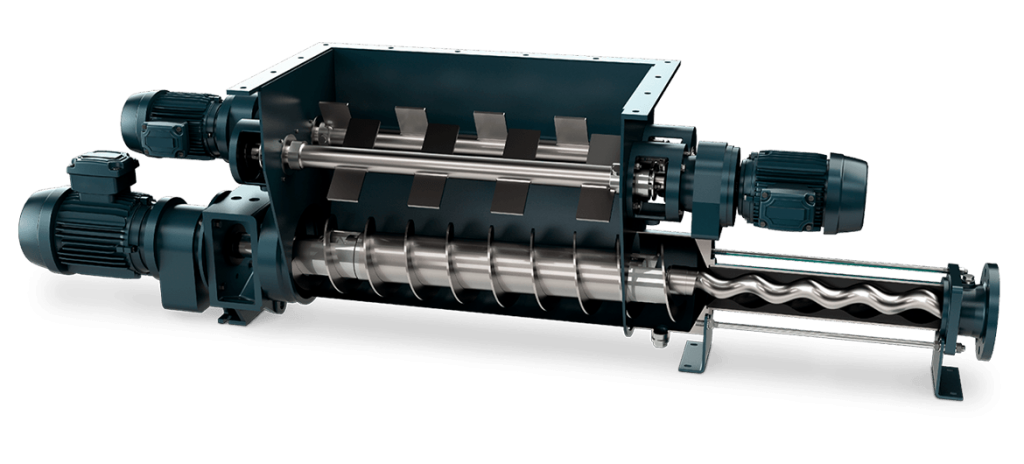

Emptying, Conveying and Dosing with NETZSCH:

Emptying, conveying or dosing – you have the application, NETZSCH has the optimal and individual solution for your problems within the different applications. NETZSCH barrel emptying systems suction themselves automatically towards the barrel bottom and empty barrels and containers almost completely in the chemical, pharmaceutical or food industries and NEMO® dispensers and hand dispensers ensure the highest degree of reproducibility and dosing accuracy in the most diverse fields of application.

NETZSCH 1C Dosing Systems

The NBE 20 twin is used to empty barrels filled with Betaseal 1965 and feed our dispenser continuously with material. Betaseal 1965 is a one-component bonding compound with excellent paint adhesion which is primarily developed in co-operation with the automobile manufacturers.

NETZSCH Barrel Emptying Pumps

The heart of the barrel emptying system is a volumetrically conveying NEMO® progressing cavity pump. When the NEMO® pump is started, a vacuum is created under the follower plate. This then simultaneously puts slight pressure on the substance in order to guarantee constant suction in the pump.

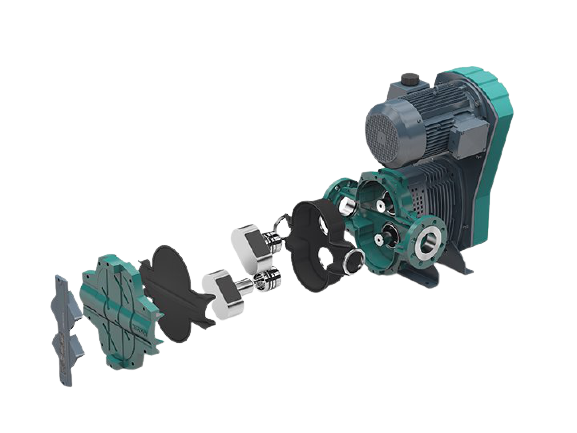

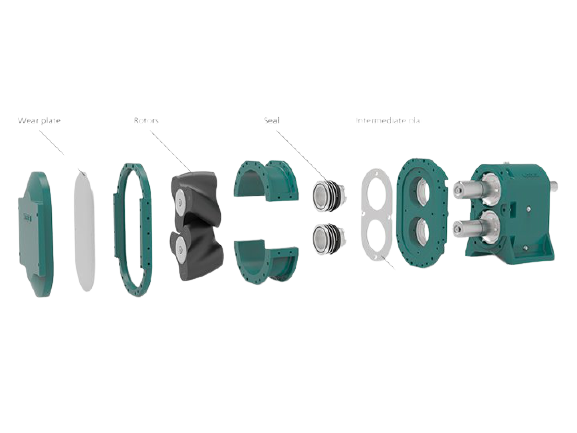

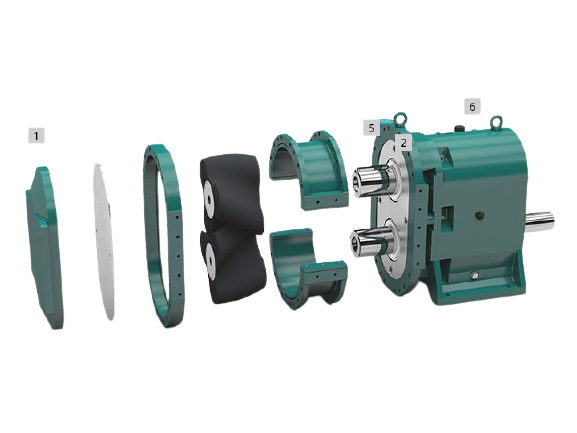

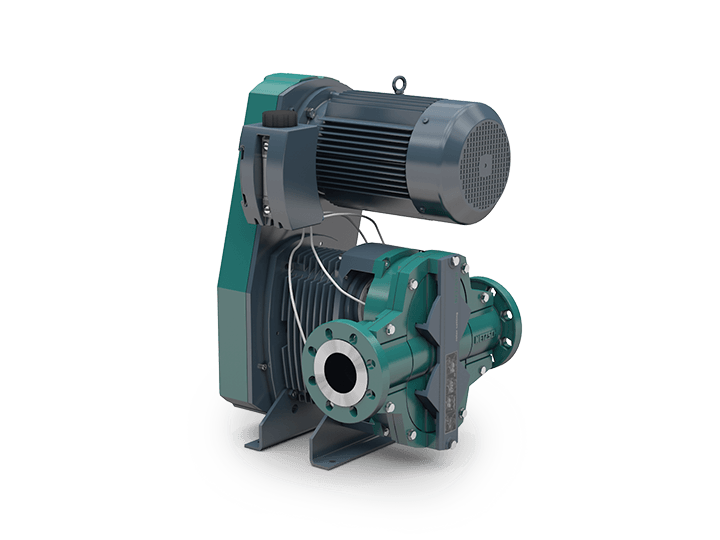

TORNADO® Industrial Rotary Lobe Pump from NETZSCH:

TORNADO® industrial rotary lobe pumps are very versatile stand-alone equipment. They are used primarily in environmental technology and the chemical industry for continuous and gentle conveyance of almost any substance while dosing in proportion to rotation speed.

Their low space requirements and high power density are some of their most important advantages. The NETZSCH TORNADO® Mobilea TORNADO® rotary lobe pump mounted onto a trailer, is ideal for use in any disaster situation.

Technical information about NETZSCH spare parts

In order to maintain the capacity and quality of your NETZSCH machines, we recommend the exclusive use of NETZSCH original spare parts. Our spare parts service allows for the delivery of standard spare parts in the USA within 24 hours.

It is in our interest to service or repair your products as quickly as possible. We have the standard parts for progressing cavity pumps, rotary lobe pumps, multi screw pumps, grinders or dosing systems in stock at our central warehouse in Exton, Pennsylvania.

For more details please visit link here.