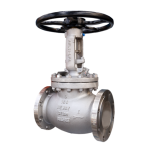

Gate, Globe & Check Valves

Cast Steel Valve

G Series Gate valves

OTC compact forged gate valves are in compliance with API602. OTC supplies a full range including bolted bonnet and pressure seal bonnet design.

GL Series (Globe)

OTC globe valves are torque seated valve which are used for on-off service as well as for throttling purpose. Globe valves are widely selected for their short travel. OTC provides two types of construction rising stem and rising-rotating stem.

S Series (Swing Check Valve)

OTC supplies a complete range of swing check valves with both internal and external hinge pin types. External control devices such as damping, locking, and manual override are part of OTC's expertise.

Stainless Steel Valve

OTC series stainless steel valves include gate, globe and check valves. These characteristics of these valves are equal to the conventional API 600 gate, globe, check valves. The valve wall thickness complies to ASME B16.34 but the valve weight is much lower which results in lower costs.

ST Series (Tilting Disc Check Valve)

OTC tilting disc check valves have the following operational advantages: quick-closing, low cracking pressure, no water hammer and can be installed in vertical pipe. Such valves can be widely applied in working conditions of high temperature steam, oil refining, petrochemical, oil field production, hydrogenation, etc.

Pressure Seal Valve

OTC pressure-seal valves are designed based on API/BS and ASME B16.34. They're widely applied within high temperature and high pressure conditions. A smart and simple rigid structure provides a reliable body-bonnet seal and low maintenance costs.

Bellow Seal Valve

Bellow seal valves are normally installed in a working condition that has strict emission requirement and once emission happens it will incur harmful influence to person and environment. This type of valve is achieved by mounting a metal bellow between the bonnet and the stem. Bellow will be driven to scale up and down when stem moves, which will eliminate possible leakage arising from stem movement

Parallel Gate Valve

GT Series (Through Conduit Slab Gate Valve)

OTC slab gate valve is a through conduit valve type. The design is ideal to minimize pressure drops and to prevent accumulation of external materials such as slurries into the valve cavity. This valve type is widely used for oil & gas transportation and complies

GP Series (Parallel Slide Gate Valve)

OTC parallel slide gate valves are designed with positional seal, using the line pressure as a sealing force. The compressed spring between the two closure members provides an initial seal during low pressure conditions. The increasing line pressure will push the closure members with higer forces aginst each other which creates the primary seal. The higher the medium pressure, the better the sealing performance. Therefore this valve type is widely used in high pressure and high temperature services such as steam and feedwater.

GT Series (Expanding Gate Valve)

OTC supplies a complete range of swing check valves with both internal and external hinge pin types. External control devices such as damping, locking, and manual override are part of OTC's expertise.

Axial Flow/Dual Plate Check Valve

SA Series (Axial Flow Check Valve)

OTC axial flow check valves are widely used where high flow performance is required and the risk of water hammer needs to be reduced to a minimum level. Additional advantages include the quick response and low noise level.

SB Series (Dual Plate Check Valve)

Due to better flow performances, smaller installation space, lower weight and easier installation, dual plate check valves are widely used in the flow control industry. OTC dual plate check valves are in compliance.

Forged Valve

G Series (Gate Valve)

OTC compact forged gate valves are in compliance. . OTC supplies a full range including bolted bonnet and pressure seal bonnet design

S,P Series (Swing, Piston Check Valve)

OTC supplies a complete range of forged swing and piston check valves designed according to the API 602 standard

Large Size Forged Valve (2 and larger)

OTC large size forged valves are designed in accordance with the API/BS/ASME standards. The valves are applied mainly in hydrogen service and exposed to high temperature and pressure.